Don't miss our holiday offer - up to 50% OFF!

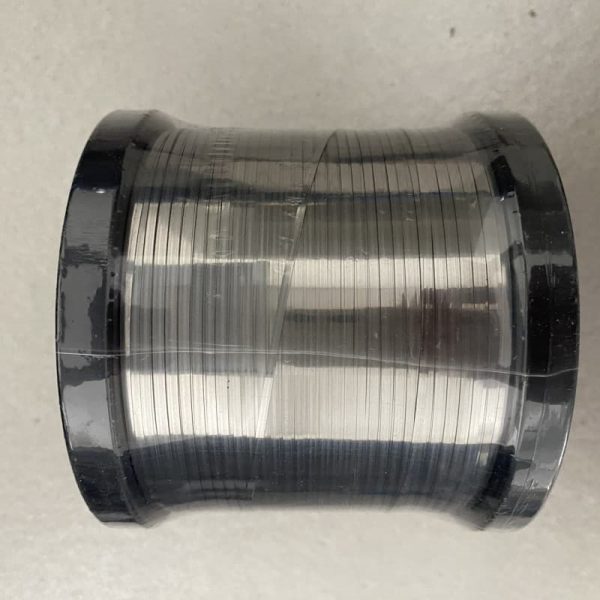

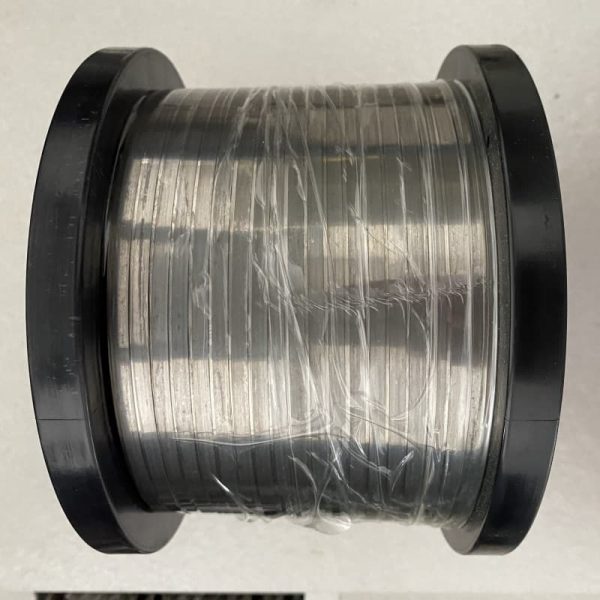

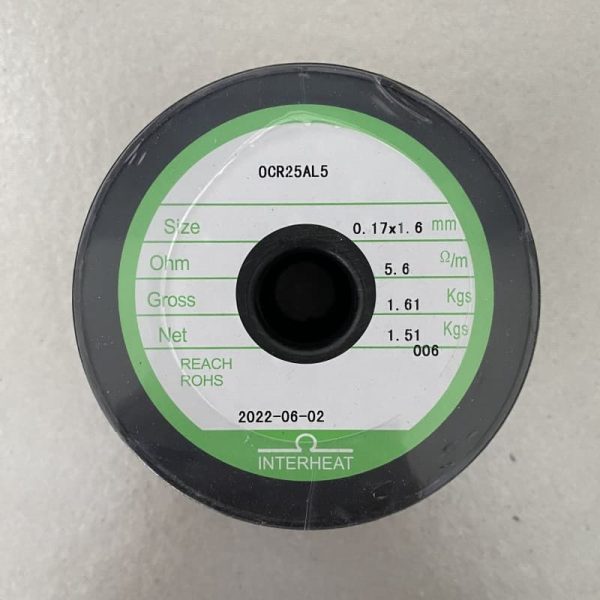

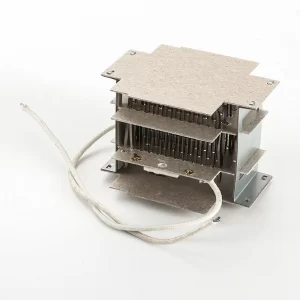

Electrical Wire Resistance Heating Flat Wire Ocr25al5 for Mica Heater

Description

Electrical Wire Resistance Heating Flat Wire Ocr25al5 for Mica Heater Packaging & Delivery

Electrical Wire Resistance Heating Flat Wire Ocr25al5 for Mica Heater Description

Resistance winding Cr20Ni80 spiral coil heating wire for heating element

About 0Cr25Al5

FeCrAl Series-0Cr25Al5 Resistance Alloy Wires is used for electrical heating element. It is Widely used in metallurgy, industrial furnace, household appliances, industry furnace, metallurgy, machinery, aircraft, automotive and other industries producing heating elements and resistance elements.

1.FeCrAl Electrocortical Resistance Heating alloys with high electrical resistivity, temperature coefficient of resistance is small, high operating temperature.

Good corrosion resistance under high temperature, and particularly suitable for use in a gas containing sulfur and sulfides, low price, it is widely used in industrial electric furnace, household appliances, far infrared device ideal heating material.

2.Nickel chromium alloy with iron resistance electrothermal high resistivity, surface body sexual well. At high temperature and high intensity, and a good performance and processing may weld nature widely used metallurgical, electrical, mechanical components and electrical manufacturing industries for doing heat resistance material.

Ni-Cr Type: Cr20Ni80, Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr25Ni20 etc. Series electric flat belt, electric fire wire.

3.Product size range: round wire dia.0.05-12mm.

flat strip thickness0.03-5mm, flat strip width0.2-500mm.

FeCrAl alloy has the characteristic of high resistivity, low temperature resistance coefficient, high operating temperature, good anti-oxidation and anti-corrosion under high temperature.

Size dimension range:

Wire: 0.01-10mm

Ribbons: 0.05*0.2-2.0*6.0mm

Strip: 0.05*5.0-5.0*250mm

Bar:10-50mm

FeCrAl alloy series: OCr15Al5,1Cr13Al4, 0Cr21Al4

OCr21Al6,0Cr23Al5,0Cr25Al5,0Cr21Al6Nb,0Cr27Al7Mo2, and etc.

|

Alloy Nomenclature Performance

|

1Cr13Al4

|

0Cr25Al5

|

0Cr21Al6

|

0Cr23Al5

|

0Cr21Al4

|

0Cr21Al6Nb

|

0Cr27Al7Mo2

|

|

|

Chemical Composition (%)

|

Cr

|

12.0-15.0

|

23.0-26.0

|

19.0-22.0

|

20.5-23.5

|

18.0-21.0

|

21.0-23.0

|

26.5-27.8

|

|

Al

|

4.0-6.0

|

4.5-6.5

|

5.0-7.0

|

4.2-5.3

|

3.0-4.2

|

5.0-7.0

|

6.0-7.0

|

|

|

Re

|

opportune

|

opportune

|

opportune

|

opportune

|

opportune

|

opportune

|

opportune

|

|

|

Fe

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

|

|

Max. continuous service temp. of element(°C)

|

950

|

1250

|

1250

|

1250

|

1100

|

1350

|

1400

|

|

|

Resistivity at 20ºC(μΩ·m)

|

1.25

|

1.42

|

1.42

|

1.35

|

1.23

|

1.45

|

1.53

|

|

|

Density(g/cm3)

|

7.4

|

7.1

|

7.16

|

7.25

|

7.35

|

7.1

|

7.1

|

|

|

Thermal conductivity(KJ/m·h·ºC)

|

52.7

|

46.1

|

63.2

|

60.2

|

46.9

|

46.1

|

—

|

|

|

Coefficient of lines expansion(α×10-6/ºC)

|

15.4

|

16

|

14.7

|

15

|

13.5

|

16

|

16

|

|

|

Melting point approx.( ºC)

|

1450

|

1500

|

1500

|

1500

|

1500

|

1510

|

1520

|

|

|

Tensile strength

|

580-680

|

630-780

|

630-780

|

630-780

|

600-700

|

650-800

|

680-830

|

|

|

Elongation at rupture(%)

|

>16

|

>12

|

>12

|

>12

|

>12

|

>12

|

>10

|

|

|

Variation of area(%)

|

65-75

|

60-75

|

65-75

|

65-75

|

65-75

|

65-75

|

65-75

|

|

|

Repeat Bending frequency(F/R)

|

>5

|

>5

|

>5

|

>5

|

>5

|

>5

|

>5

|

|

|

Hardness (H.B.)

|

200-260

|

200-260

|

200-260

|

200-260

|

200-260

|

200-260

|

200-260

|

|

|

continuous service time(Hours/ ºC)

|

—

|

≥80/1300

|

≥80/1300

|

≥80/1300

|

≥80/1250

|

≥50/1350

|

≥50/1350

|

|

|

Micrographic structure

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

|

|

Magnetic properties

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

|

Applications:

Heating equipment: industrial furnace, civil heating appliance, various electrical resistors and

locomotive braking resistor.

Features:

1. High Temperature Resistance

2. Excellent Insulating Property

3. Efficient Thermal Conductivity

4. Significant Energy-saving

5. High nickel, high resistance

Packing Shipping

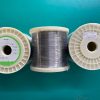

Package of FeCrAl heating wire: Goods are supply in coil or on spool, Carton or wooden case in outside.

as demanded. Shipping of FeCrAl heating wire: By vessel or by train from any Chinese port,

Samples can be delivered by International express.

|

Lead time

|

||||

|

1-50kg

|

2 working days (packing boxes)

|

|||

|

51-100kg

|

3 working days (packing boxes)

|

|||

|

101-500kg

|

5 working days (use Carton or wooden case in outside)

|

|||

|

500kg-1000kg

|

7 working days (use Carton or wooden case in outside)

|

|||

FAQ

Q1: Are you trading company or manufacturer?

A1: We are factory for manufacturing heating products for over 18 years now.

Q2: Can I get the pre-production samples?

A2: Sure, it is welcome, we will send you sample, after you confirm.

Q3: Do you provide samples? is it free or extra?

A3: Yes, we could offer the sample for free charge, would you mind paying the freight fee?

Q4: How do we place an order?

A4: Please kindly send us an email specifying the item, quantity, color or other specification to place an order.

Q5: How do we make the payment?

A5: We accept Western Union, TT.

Q6: What’s the delivery time?

A6: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q7: How would the goods be shipped?

A7: We ship via DHL, UPS, FedEx or TNT, EMS, Airline and sea shipment are also available.

Q8: Is OEM/ODM available?

A8: Yes, it’s available. The OEM MOQ is 500pcs. For details, please kindly contact the salesperson.

Q9: How can I contact with your company?

A9: We are always ready to serve you via Email, Telephone, Skype, or wechat.

Q10. Do you test all your goods before delivery?

A10: Yes, we have 100% test before delivery.

Q11: How do you make our business long-term and good relationship?

A11: We keep good quality and competitive price to ensure our customers benefit;

A12: We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Reviews

There are no reviews yet.